Scientific methods in the early Twentieth Century revealed that asbestos was the most effective and cost-efficient insulating material for fire resistance. Shipbuilders commonly incorporate asbestos into various components such as gaskets, seals, and fireproofing materials due to its ability to withstand high temperatures and resist corrosion, ensuring the safety and durability of vessels. This mineral, however, has left a toxic legacy affecting thousands of workers and environments around the globe.

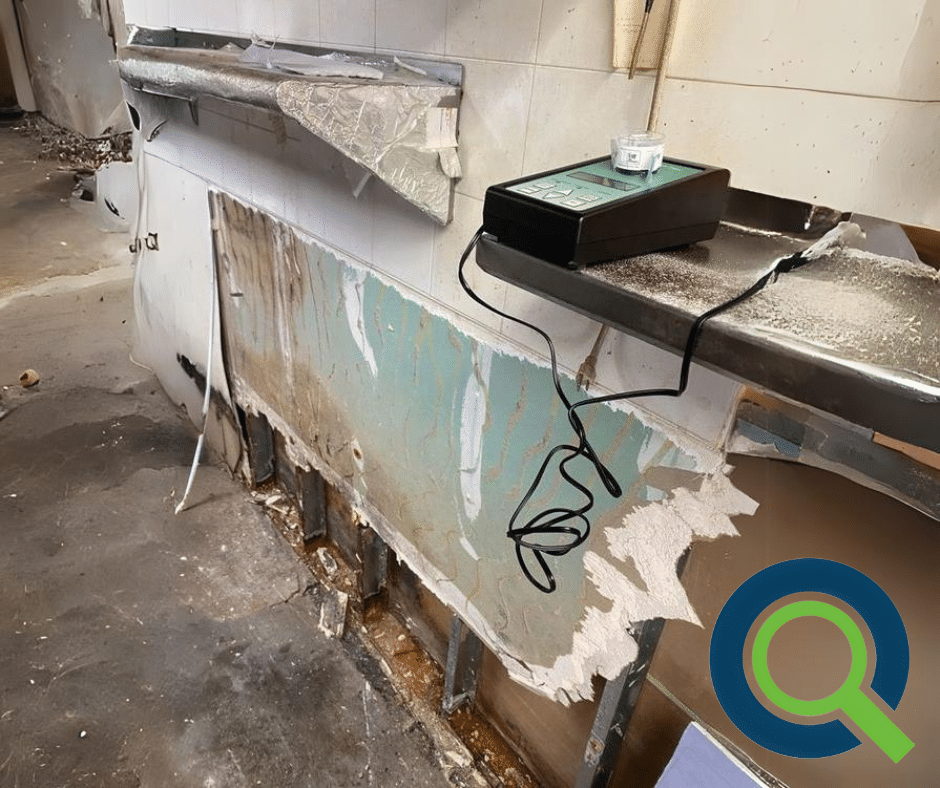

Over the years, it became evident that asbestos exposure was linked to a host of serious health issues, including asbestosis, lung cancer, and mesothelioma—a rare and aggressive cancer almost exclusively caused by asbestos exposure. Despite the well-documented risks, ships decommissioned in shipyards today continue to contain old legacy asbestos products, posing ongoing risks to those involved in decommissioning and salvage operations.

Protective measures and regulations have been implemented to mitigate the environmental impact of asbestos in shipbuilding and ensure safer working conditions. Yet, the inertia of past practices means that the ripple effects of asbestos use are still felt in the industry and environment today. The challenge resides in managing the remnants of asbestos-containing materials and adequately addressing the health consequences for those historically exposed.

Historical Use of Asbestos in Shipbuilding

The proliferation of asbestos in shipbuilding during World War II marked a significant period plagued by severe health impacts for shipyard workers. A reliance on asbestos insulation for its fireproofing qualities inadvertently exposed thousands to hazardous conditions, setting the stage for later diseases like lung cancer, mesothelioma, and asbestosis.

Shift to Asbestos Insulation During World War II

With the advent of World War II, there was an unprecedented rise in the use of asbestos as it became an integral material for insulation in naval vessels. The U.S. Navy mandated asbestos for fireproofing and insulating purposes, increasing the commodity’s utilization in the shipbuilding industry. Essential ship components like boilers, pipes, and gaskets were often made with asbestos-containing materials to enhance durability and fire resistance.

Prominent Shipyards and Asbestos Exposure

The United States has several prominent shipyards linked to remarkable levels of asbestos exposure. Workers at these sites routinely handled asbestos insulation and other asbestos-containing products such as cement, boilers, and gaskets without knowing the grave health risks. Shipyards across the United States, including those in Harland and Wolff, became hotspots for toxic exposure, resulting in numerous health issues that would emerge years later.

Role of the Navy and Asbestos Products

The Navy played a pivotal role in furthering the use of asbestos products within shipbuilding, specifying materials like asbestos cement and piping for extensive use in naval ships. The U.S. Navy considered asbestos indispensable for safeguarding ships from the threat of fire, especially in combat scenarios. However, the properties that made it an asset in ship construction also posed lethal health risks for those involved in installing and maintaining asbestos insulation and other applications within naval vessels.

Health Impacts and Diseases from Asbestos

Prolonged exposure to asbestos in shipbuilding has been conclusively linked to severe health impacts, with diseases such as mesothelioma and lung cancer as particularly fatal consequences. The latent period between exposure and disease onset makes these conditions especially insidious.

Development of Asbestos-Related Diseases

When individuals inhale asbestos fibers, these tiny particles can lodge in the lungs and pleura. Over time, these fibers may lead to inflammation and scarring that result in a range of asbestos-related diseases. Asbestos exposure, particularly among shipyard workers, typically has a 20 to 50-year latency period. This duration before symptom onset makes early diagnosis challenging.

Mesothelioma, a type of cancer that affects the thin layer of tissue covering most internal organs (the mesotheli), is a prime example of such diseases. While mesothelioma can affect different areas of the body, pleural mesothelioma, which targets the lining of the lungs (pleura), is the most common. Similarly, lung cancer, another serious condition linked to asbestos, arises when fibers cause cellular damage, leading to malignancy within the lung tissue itself.

Recognition of Mesothelioma and Lung Cancer

The grave health risks posed by asbestos in the shipbuilding industry came to light as medical professionals observed increased rates of cancers in exposed populations. It was noted that shipyard workers displayed significantly higher mortality rates from conditions such as mesothelioma and lung cancer compared to the general population. The environment of shipyards, with confined spaces and poor ventilation, exacerbated the intensity of asbestos exposure, thus increasing the likelihood of developing these life-threatening diseases.

Research has demonstrated a clear cause-and-effect relationship between asbestos and lung cancer. The risk is dose-dependent – the more extensive the exposure, the higher the risk. Both mesothelioma and lung cancer from asbestos exposure have high mortality rates, making them pressing occupational health concerns. Despite safety improvements and regulations, for those with past asbestos contact, the threat remains due to the diseases’ long latency periods.

Regulation and the Phase-Out of Asbestos

The battle against asbestos in maritime construction has been led by stringent regulations and global bans. Key regulatory bodies like OSHA and the EPA have been instrumental in setting safety standards, while a worldwide movement has seen the material largely banned in shipbuilding.

Implementation of Safety Standards by OSHA and EPA

The Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) have implemented safety standards to limit asbestos exposure. OSHA’s regulations specifically address asbestos in the workplace, including shipyards. The Asbestos Hazard Emergency Response Act, enforced by the EPA, requires schools to inspect for asbestos and take action to reduce asbestos hazards. These regulations have been a critical part of efforts to protect workers in the United States, including those in states like California, where shipbuilding was previously a source of significant asbestos exposure.

- OSHA Standards: Enforcement includes permissible exposure limits (PELs), exposure monitoring, and medical surveillance.

- EPA Regulations: Emphasize abatement procedures, disposal guidelines, and public education on asbestos hazards.

Global Shift and Asbestos Bans

Countries around the world have recognized the asbestos hazard and have moved to ban the substance. Italy and Japan are among the nations that have prohibited asbestos in ship construction. The International Maritime Organization (IMO) also prohibits the new installation of materials containing asbestos on ships, aligning with wider efforts to eradicate its use globally. This alignment indicates a broader commitment to enhance safety standards within the maritime industry and reflects the global consensus on the dangers of asbestos.

- International Bans: Over 60 countries, including the European Union member states, have total bans on asbestos.

- SOLAS Regulation: Ships built after 2011 are forbidden from using any asbestos-containing materials as per the Safety of Life at Sea (SOLAS) regulations.

Legal and Compensation Efforts for Victims

The legal landscape for asbestos exposure in shipbuilding is marked by exhaustive litigation and substantial efforts to compensate the victims, especially veterans, who suffer from mesothelioma and other asbestos-related diseases.

Asbestos Litigation and Compensation for Veterans

Veterans, particularly those involved in shipbuilding, form a significant group affected by asbestos use. Many have developed mesothelioma, a malignant tumor caused by inhaled asbestos fibers. Since traditional VA benefits may not cover all the healthcare costs for asbestos-related diseases, former military shipyard workers have legal recourse. They may file lawsuits against asbestos manufacturers, such as Johns Manville, that historically supplied asbestos products to the military. These legal actions aim to hold manufacturers accountable for the health hazards their products created.

Veterans are also entitled to benefits through the Department of Veterans Affairs if they can prove their disease is service-related. In some cases, mesothelioma or lung cancer diagnosis directly links to asbestos exposure on naval ships and shipyards, making them eligible for compensation.

- Examples of compensation awarded to veterans include:

- Disability Benefits: Monetary payment for impaired health due to service-connected asbestos exposure.

- Health Care: Medical treatment for diseases resulting from asbestos-related service activities.

- Dependency & Indemnity Compensation (DIC): A monthly benefit for eligible survivors of veterans who died from a service-connected condition.

Continuing Legal Battles and Asbestos Trust Funds

The legal battles over asbestos have led to the creation of asbestos trust funds. These funds were established as part of the bankruptcy process for manufacturers proven to have contributed to the adverse health effects associated with asbestos. They are designed to provide long-term compensation to individuals with documented health issues due to asbestos exposure, including shipyard workers and Navy veterans.

The National Institute for Occupational Safety and Health (NIOSH) monitors asbestos exposure, contributing crucial data supporting those affected’s claims. Lawsuits continue as victims seek compensation for their illnesses, and lawyers work within the framework of established trust funds and through the court system to secure just compensation for their clients.

- Notable trust funds include:

- Johns Manville Trust: One of the largest, established after the company filed for bankruptcy in 1982.

- Numerous other funds were created following the bankruptcy of multiple asbestos manufacturers.

Litigation and compensation for asbestos exposure remain, therefore, both a recourse and a resource for those who have suffered as a result of working with this toxic substance, particularly within the shipbuilding industry. The efforts reflect both acknowledgment of the past wrongs and an attempt to mitigate the long-term consequences for the victims and their families.

Read more: Proven Strategies for Preventing Mold Growth in Humid Climates.